RAC

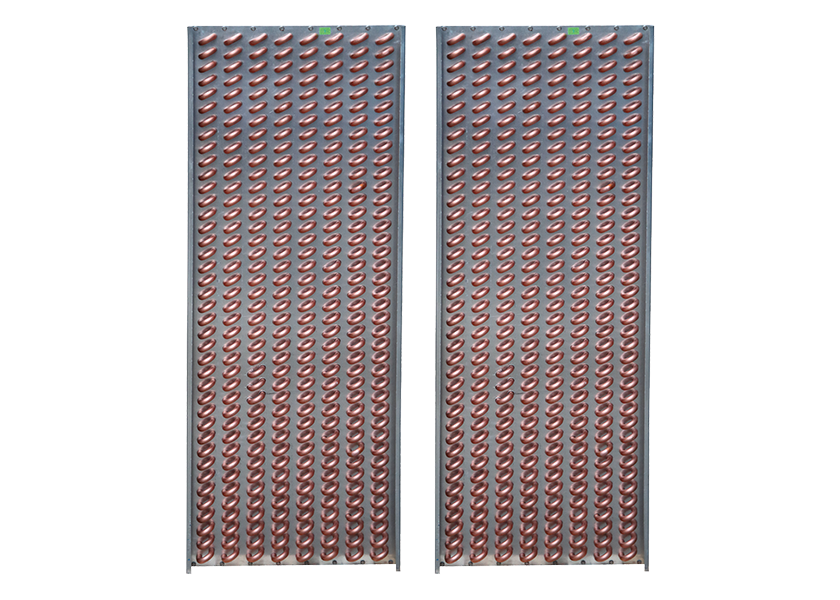

Two or more coils enable heat transfer and consequently heat can be recovered between the supply air and exhaust air with the help of the circulation pump and control system. It’s a sensible type heat exchanger. There is only heat transfer between the two airs, but no humidity transfer. Supply air and exhaust air can be located far from each other. The two airs are not mixed to each other and there is no moving part. These are some typical properties of this heat exchanger.

Heat recovery temperature efficiency, air and water side pressure drop, air and recirculation liquid flow, condensed water freezing risk at winter time are calculated in our company with a software developed specially for this purpose. Fin geometries can be designed according to requested row numbers in staggered or inline form. Coil size can be up to 12 m in length and 3m in height. Our heating and cooling coils are certified by EUROVENT.

At winter time, humidity in the air condense on the fins of coils. To prevent energy efficiency loss condensates water should be avoided from freezing. Glycol should be used in order to prevent freezing in the circulation system.

Mechanical Properties:

Fins are aluminum as a standard. Upon request marine aluminum, industrial pre-coated epoxy or hydrophilic fins can be also used. The pipes are from copper. Upon request, tinned copper or aluminum tubes can be used. Frame can be made from galvanized steel, aluminum alloy, stainless steel or some other special materials. Heat exchangers can be completely painted. Inlet and outlet pipes can be threaded or flanged.

Heat recovery system diagram consists of 2 cooling (C) and 2 heating (H) coils.