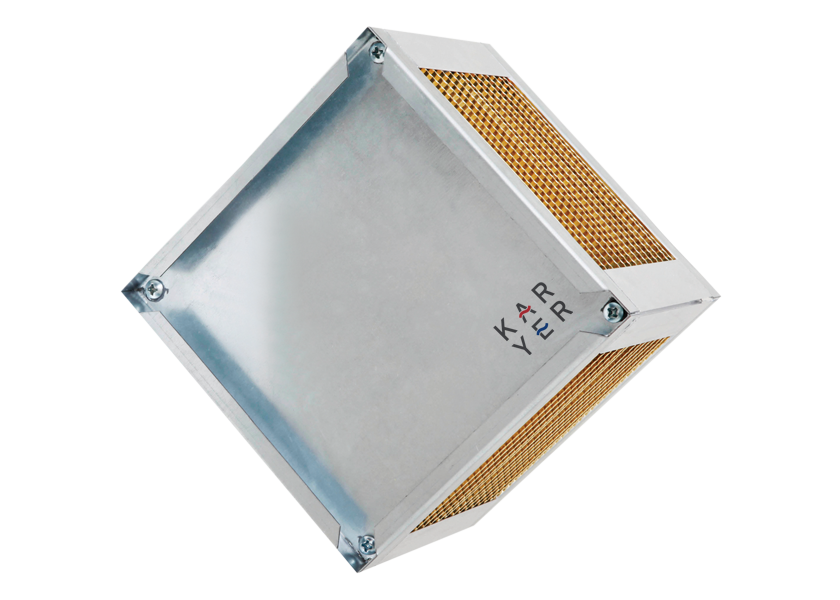

PHE Cross

Cross-flow Heat Recovery Plate Exchangers (Cross PHE)

Multiple air channels formed by fins generate heat transfer between exhaust and supply air and consequently heat recovery occurs. Even if there are sensible and total energy types, Karyer only manufacture sensible type. There is heat transfer between the two airs but there is no humidity transfer. Exhaust air and supply air are passing through the heat exchanger in a cross form. Supply air and exhaust air locations are close to each other, the two airs get mixed at minor rate and there is no moving part. These are some typical properties of this heat exchanger.

Heat recovery, temperature efficiency, both sides air pressure drop and condensed water freezing risk at winter time are calculated in our company with a software developed specially for this purpose.

At winter time, humidity in the air condense on the fins of coils. To prevent energy efficiency loss and damage in the exchanger, condensed water should be avoided from freezing.

APHE series of plate heat exchangers are certificated by EUROVENT.

Mechanical Properties:

Fins are aluminum as a standard. Upon request, marine aluminum, industrial pre- coated epoxy or hydrophilic fins can be also used. Frame can be manufactured from special aluminum profile covers can be manufactured from galvanized sheet metal or aluminum.

Nomenclature: APHE A 20 5,3 034 N C

APHE: Model description of cross flow plate type heat recovery exchanger

A: Aluminum E: Epoxy coated aluminum H: Hydrophilic coated aluminum M: Aluminum Alloy

20: Edge size 20, 30, 40, 50, 60, 80 cm etc.

5,3: Fin spacing mm, 3 to 8 mm depends on the edge size

034: Fin length cm, up to 200 cm

N: Corner sealing (mastic) type N: standard S: Special C: Corner profile structure

Application Samples

Cross-flow heat recovery plate exchangers can be connected in series to increase the efficiency. (Please check Heat Recovery Heat Exchangers catalogue for more information.)